Product Overview

Thin film coated magnet wire is made of oxygen-free copper rod or electrical round aluminum rod with a specific mold suppress or wire drawing cooling treatment, and then coated in copper (aluminum) conductor with two or more layers of film (including polyester film, polyimide film, and so on) winding, After heating, the fluorine 4.6 on the composite film melts, so that the thin film and the conductor bond into a whole,to achieve the effect of insulation suitable for oil-immersed transformer wiring and similar electrical winding. Electric bare copper (aluminum) wire produced by the extrusion technique is a good material for the manufacturing of thin film coated wire.

Product Material

Aluminum flat wire should meet the requirements of GB5584.3-2009, and the resistivity at 20℃ is not more than 0.0280Ωmm2/ m

Copper flat wire should comply with the provisions of GB5584.2-2009, and the resistivity at 20℃ is not greater than 0.017241Ωmm2/ m

Production Scope

Aluminum flat wire:Narrow side:1.0mm-8.0mm

Wide side: 3.0mm-25.0mm

Copper flat wire: Narrow side:0.9mm-5.6mm

Wide side: 2.0mm-16.0mm

Aluminum/Copper round wire: ɸ1.7- ɸ8.0

Product Advantages

● Lower Cost, smaller Size

● Lighter Weight

● Reliability Improvement

● Increase of Reserve Capacity

Product Parameter

After the polyimide film wire is bent on a round rod with a wide edge and a narrow edge, respectively, as specified in the following table, the cladding shall be wound without cracking to a bare conductor.

Nominal size(mm) | Round rod diameter |

2.00<b≦8.00 | 10b |

8.00<b≤16.00 | 15b |

0.8<a≤5.60 | 10a |

Breakdown voltage of polyimide film coated copper/Aluminum wire

Winding method | Insulation thickness(mm) | Breakdown voltage no less than | |

Norminal value | Tolarance | ||

2 layers polyimide self-locking wrapping | 0.15 | ±0.03 | 6000 |

2 layers polyimide lap wrap in opposite directions | 0.15 | ±0.03 | 6000 |

3 layers polyimide lap wrap in opposite directions | 0.23 | ±0.03 | 7000 |

Certificates

Customer Visits

Packaging For Shipment

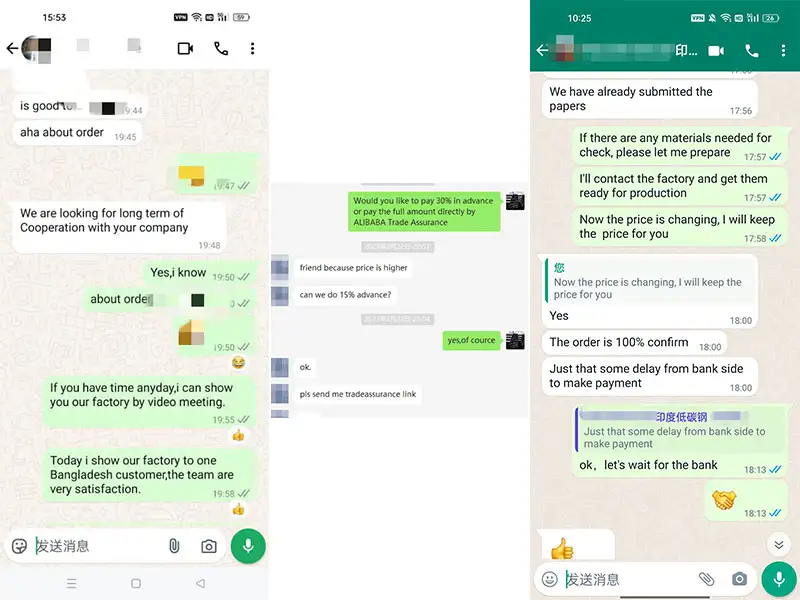

Chat Log

Factory Workshop

Areas Of Application

Thin Film Covered Winding Wire

Thin film coated magnet wire is made of oxygen-free copper rod or electrical round aluminum rod with a specific mold suppress or wire drawing cooling treatment.

Contact Us

Classification

FAQs

Why should you buy from us not from other suppliers?

What is the standard of package?

What is your product scope?

How long has Yubian been worked in electric industry?

What is your payment terms ?

How long is your delivery lead time ?

What is your MOQ?

Do you accept customized service ?

Are you a trading company or manufacturer ?