Product Overview

Cable paper covered wire is made of oxygen free copper rod or electrician round aluminum rod by a certain specification mold extrusion or drawing annealing treatment of wire, and then in copper (aluminum) conductor wrapped two or more layers of insulation paper (including telephone paper, cable paper, high voltage cable paper, turn to turn insulation paper, etc.) winding wire, suitable for oil-immersed transformer coil and other similar electrical winding wire. Electrical bare copper (aluminum) wire produced by extrusion process is the ideal material for the production of cable paper covered wire.

Paper-covered copper flat wire has some unique characteristics compared with other types of wire and cable. First of all, because it uses paper-wrapped insulation materials, it has high insulation performance and can effectively prevent the leakage and interference of current. Secondly, the flat shape of the paper-covered copper flat wire makes it more convenient during installation and wiring, saving space and reducing clutter. In addition, the paper-covered copper flat wire has excellent electrical conductivity, can transmit larger current and higher voltage, and is suitable for a variety of high-load electrical equipment. Finally, the paper-covered copper flat wire has good wear resistance and aging resistance, and can maintain stable electrical properties in long-term use.

Product Material

Aluminum flat wire should meet the requirements of GB5584.3-2009, and the resistivity at 20℃ is not more than 0.0280Ωmm2/m

Copper flat wire should comply with the provisions of GB5584.2-2009, and the resistivity at 20℃ is not greater than 0.017241Ωmm2/m

Product Parameter

Conductor diameter | 1.000≤d≤5.00 | |||||||||

Insulation thickness(mm) | 0.3 | 0.45 | 0.8 | 1.2 | 1.8 | 4.25 | ||||

Allowable devision(mm) | ±0.05 | ±0.05 | ±0.10 | ±0.12 | ±0.15 | ±0.30 | ||||

Note: For the thickness between the two specifications, the deviation corresponding to the larger specification is taken | ||||||||||

Cable paper wrapped flat wire | ||||||||||

Insulation thickness ɸ (A-a)OR(B-b)(mm) | Deviation /% | |||||||||

Greater | LEQ | |||||||||

— | 0.5 | ±10 | ||||||||

0.5 | 1.25 | ±7.5 | ||||||||

1.25 | — | ±5 | ||||||||

Note: The insulation thickness is allowed to exceed the specified value if the maximum external dimension does not exceed the maximum conductor size plus the maximum insulation thickness specified in this regulation | ||||||||||

Bending standard for telephone cable paper covered wire | ||||||||||

Insulation thickness/mm | Experimental method | Test rod diameter | Insulation thickness/mm | Test rod diameter | Test rod diameter | |||||

0.30≤ σ≤0.80 | Winding | 100 | 0.30≤ σ≤0.80 | Wide edge bending | 150 | |||||

1.20≤ σ≤4.25 | 150 | 1.20≤ σ≤4.25 | 200 | |||||||

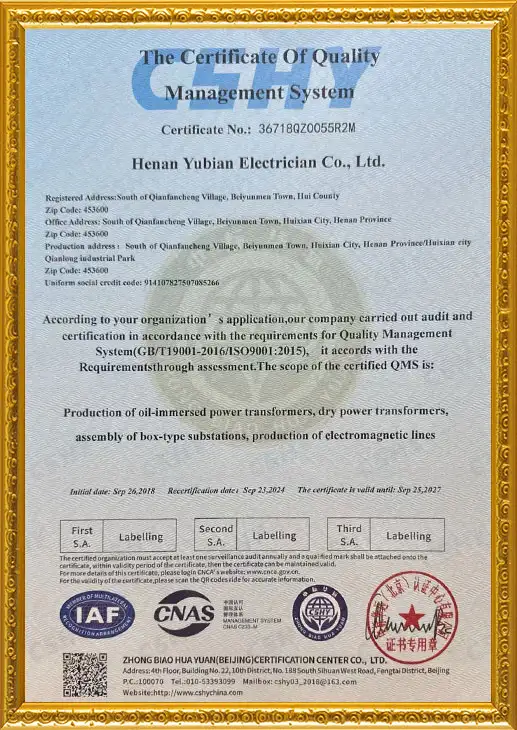

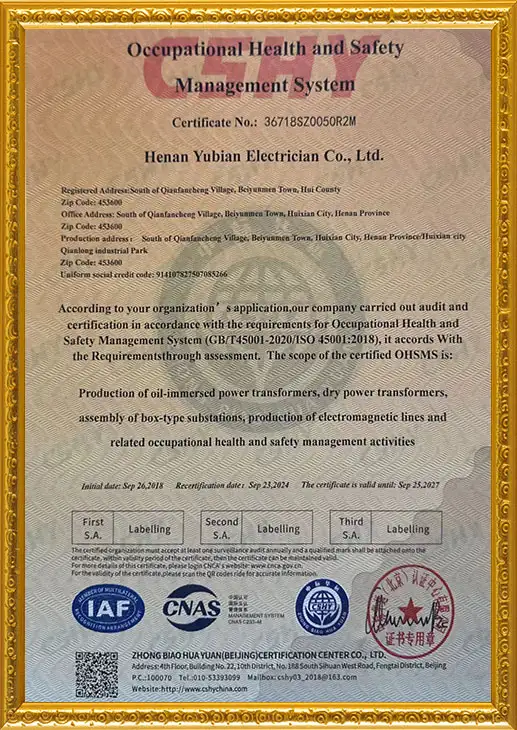

Certificates

Customer Visits

Packaging For Shipment

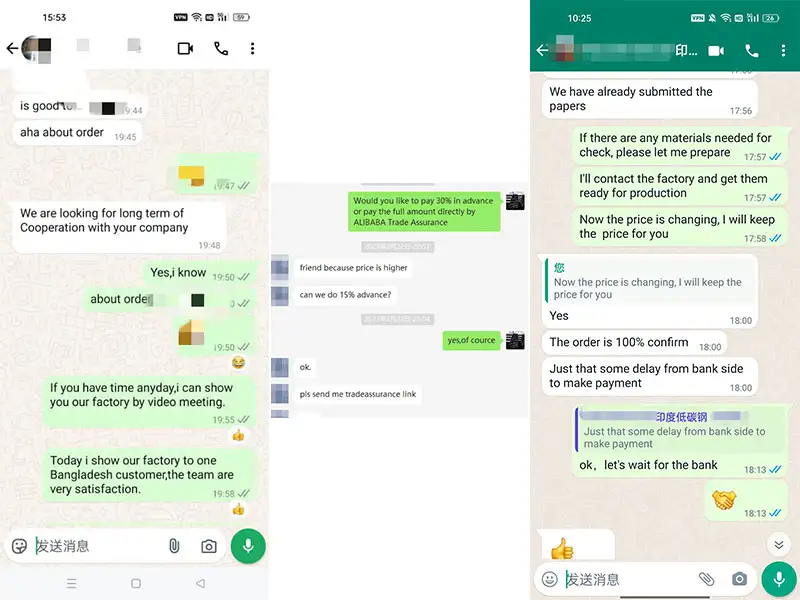

Chat Log

Factory Workshop

Areas Of Application

Cable Paper Covered Winding Wire

Paper-covered copper flat wire has some unique characteristics compared with other types of wire and cable.

Contact Us

Classification

FAQs

Why should you buy from us not from other suppliers?

What is the standard of package?

What is your product scope?

How long has Yubian been worked in electric industry?

What is your payment terms ?

How long is your delivery lead time ?

What is your MOQ?

Do you accept customized service ?

Are you a trading company or manufacturer ?